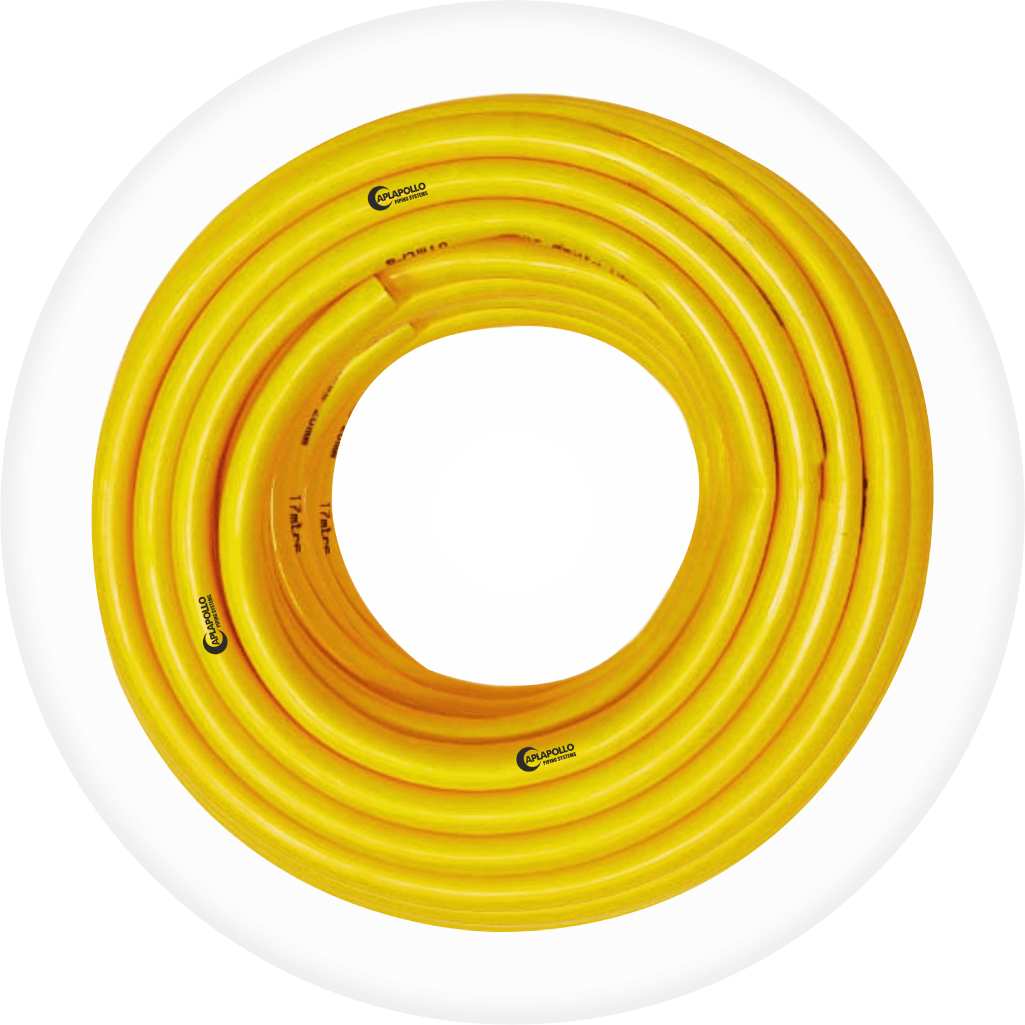

MDPE & HDPE GAS PIPING SYSTEM

Introduction

In modern gas distribution, the choice of materials and systems plays an important role in ensuring efficiency, durability, and above all, safety. Medium-Density Polyethylene (MDPE) and High-Density Polyethylene (HDPE) piping systems have revolutionized the gas industry due to their superior properties and long service life. Used extensively for both residential and industrial applications, MDPE & HDPE pipes have become the best solution for safe gas transportation.

Backed by leading gas pipe manufacturers, MDPE and HDPE gas piping system is setting new standards for performance and reliability. Medium-density polyethylene (MDPE) and high-density polyethylene (HDPE) pipes have consistently delivered high performance in transporting natural gas, PNG, propane, LPG, and biogas. They are lightweight, durable (with a lifespan of more than 100 years) and corrosion resistant.

Gas distribution was one of the first large-scale applications for polyethylene pipes, and many systems installed over six decades ago continue to operate successfully today. Over 90 percent of the pipes used in natural gas distribution are manufactured from plastic, with 99% of these being polyethylene.

In this context, APL Apollo’s polyethylene gas pipes represent the safest and most cost-effective solution for piped gas distribution systems. Widely used in both domestic (city gas distribution) and industrial sectors, these MDPE and HDPE gas piping systems offer leak-proof, durable, homogeneous, and corrosion-resistant performance. APL Apollo gas pipes are the preferred choice of all major City Gas Distribution (CGD) and Coal Bed Methane (CBM) companies across India, reinforcing its position as a trusted leader in gas infrastructure solutions.

Technical Specifications

APL Apollo Gas Pipes are manufactured as per the specifications given below:

- Pipe Range: 20 MM To 315 MM, SDR 11, 17

- EF Fittings: 20 MM To 355 MM, suitable for pressures of 7/12.5/16 KGF/CM2

- Straight Lengths: Available in 6 M and 12 M; all sizes offered, with coils available for up to 140 MM OD

- Material Grades: PE 80 (Yellow), PE 100 (Orange), PE 80 & PE 100 (Black)

WHY SHOULD YOU CHOOSE APL APOLLO

MDPE & HDPE GAS PIPING SYSTEM?

LONG LIFE

FLEXIBILITY

ISI CERTIFIED PRODUCT

CORROSION RESISTANT

LIGHT WEIGHT

LEAK-FREE JOINTS

WITHSTAND THE HIGH-PRESSURE FLOW

EASIER INSTALLATION AND MAINTENANCE

MDPE & HDPE GAS PIPING SYSTEM