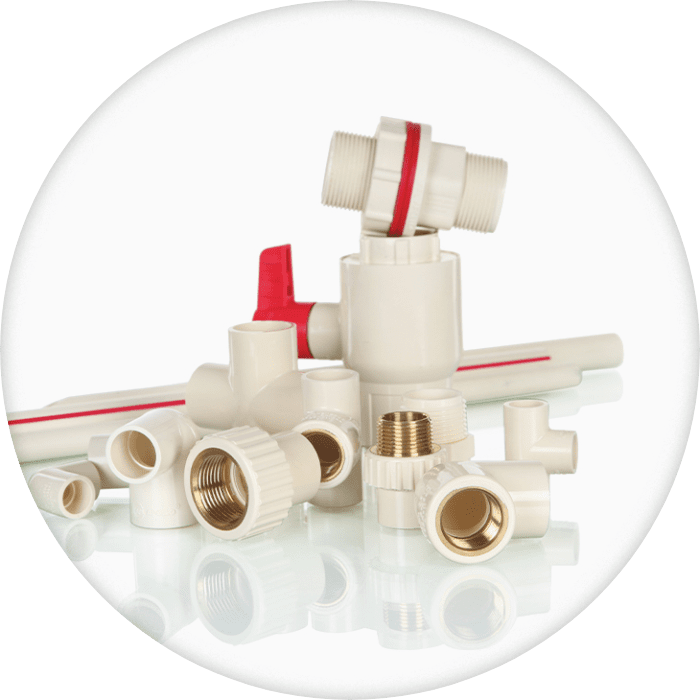

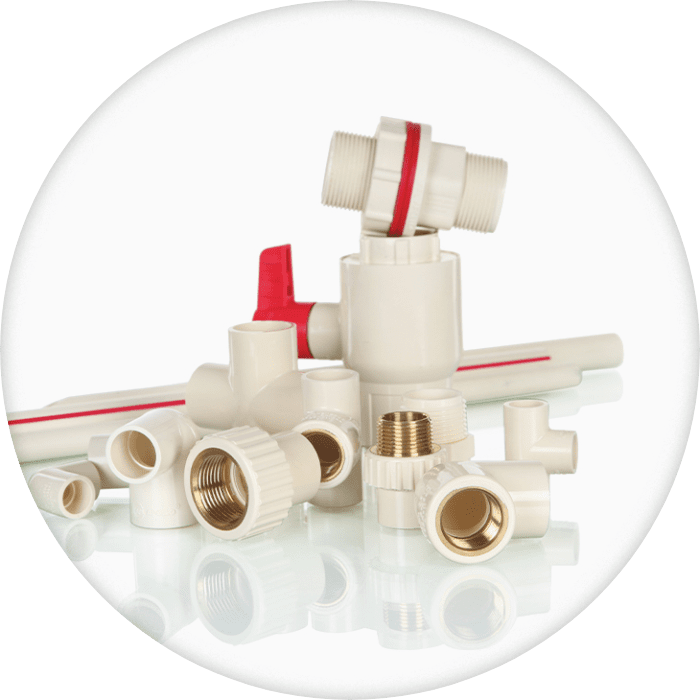

PVC is a material that is commonly utilized in the manufacture of pipelines. PVC comes in two varieties: UPVC and CPVC. The primary distinction between UPVC and CPVC is that UPVC is produced without the addition of plasticizers, whereas CPVC is produced with the addition of plasticizers and chlorination. When it comes to temperature resistance, however, CPVC can withstand a larger degree of heat than UPVC.

FEATURES OF CPVC PIPE

1. LONG LIFE

2. IDEAL FOR HOT AND COLD WATER

3. ISI CERTIFIED PRODUCT

4. UV RESISTANCE

5. LEAKPROOF

6. LOW THERMAL EXPANSION

7. CORROSION-FREE

8. BACTERIA FREE

FEATURES OF UPVC PIPE

1. MANUFACTURED FROM QUALITY RAW MATERIAL

2. WORLD CLASS MACHINING

3. LONGEVITY OF LIFE CYCLE

4. EASY HANDLING, TRANSPORTATION, AND INSTALLATION

5. LEAK-PROOF JOINTS

6. MANUFACTURED UNDER STRINGENT QUALITY STANDARDS

7. LEAD-FREE

8. EXCELLENT CHEMICAL RESISTANCE

STEPS FOR CPVC AND UPVC PIPES INSTALLATION

MEASURING

we should measure the length of the pipe in an accurate manner and make a marking using the pen to make a required and neat joint. Make sure that the pipe and fittings are adaptable.

CUTTING

1. Cut the pipe with a sharp saw/cutter as squarely as possible ( at 900) which provides optimal bonding area within a joint.

2. Check and inspect pipe ends thoroughly before making a joint.

3. If you see a crack then cut off a minimum of 25mm beyond the noticed crack before proceeding.

DEBURRING/BEVELING

1. If there are burrs in and on the end of the fittings during the assembly then it can obstruct the proper contact between the pipe and socket.

2. The burrs should be removed from both in and outside of the pipe.

3. A slight bevel on the pipe's end will make it easier to insert the pipe into the fitting socket.

FITTING PREPARATION

1. Wipe the dirt and moisture from the fittings, sockets, and pipe by using a clean dry cloth.

2. Dry fit the pipe to ensure a complete entrance into the bottom of the fitting socket and create a visible marking with a dark marker.

SOLVENT CEMENT APPLICATION

1. You can use APL Apollo solvent cement (ASTM F-493) for the perfect solvent weld joint.

2. Apply an even coat of cement on the end of the pipe and also inside the fitting socket while making a joint.

3. The solvent should have a flowing consistency like syrup. Avoid lumpy or thickened solvent cement.

ASSEMBLY

1. Insert a pipe into a socket just after applying solvent cement.

2. Rotate the pipe 1/2 or 1/4 while inserting. Maintain even distribution of cement within the joint during motion or rotation.

3. Align the fittings properly and leave it for 10-20 seconds to make the joint set-up.