Ultima PVC-O Pipes

Introduction

Looking to elevate your water transportation experience? Then APL Apollo Ultima PVC-O pipes are your ultimate solution! Engineered with cutting-edge technology, these pipes redefine excellence in high-pressure water applications. Crafted through a revolutionary molecular orientation process, these pipes maintain the inherent advantages of PVC while enhancing their physical and mechanical properties. Ideal for medium- and high-pressure water networks, they excel in irrigation, potable water supply, fire extinguishing, and pumping systems.

Beyond performance, they contribute significantly to sustainable development, making them an eco-friendly choice. With unbeatable impact resistance, flexibility, and ease of installation, these PVC-O pipes are the top-tier solution for your water transportation needs. Choose APL Apollo, one of the best PVC-O pipe manufacturers, and experience innovation, reliability, and sustainability in every drop.

Technical Specifications

APL Apollo PVC-O Pipes are manufactured as per the standards given below:

- As per IS 16647: 2017 and ISO 16422

- APL Apollo Ultima PVC-O 500 (C1.4 Pipe)

Nominal Pressure Bar - PN12.5, PN16, PN20 and PN25 - APL Apollo Ultima PVC-O 500 (C1.6 Pipe)

Nominal Pressure Bar: - PN10, PN12.5, PN16, PN20 and PN25 - APL Apollo Ultima PVC-O 450 (C1.4 Pipe)

Nominal Pressure Bar: - PN10, PN12.5, PN16, PN20 and PN25 - APL Apollo Ultima PVC-O 450 (C1.6 Pipe)

Nominal Pressure Bar: - PN10, PN12.5, PN16, PN20 and PN25

WHY SHOULD YOU CHOOSE APL APOLLO

Ultima PVC-O Pipes?

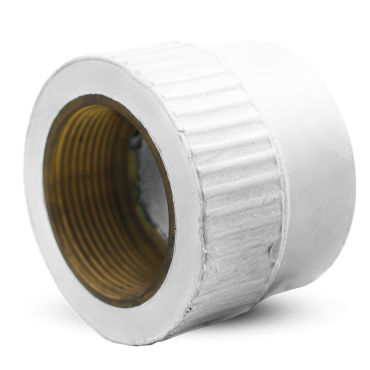

MANUFACTURED FROM QUALITY RAW MATERIAL

WORLD-CLASS MACHINING

LONGEVITY OF LIFE CYCLE

LEAK PROOF JOINTS

EASIER INSTALLATION AND MAINTENANCE

LIGHTER WITHOUT COMPROMISING STRENGTH

WITHSTAND THE HIGH-PRESSURE FLOW OF WATER

APL Apollo PVC-O Pipes

Call to place your order via phone

Toll Free No. : 1800 121 3737

Toll Free No. : 1800 121 3737

Or

Request a callback

Call to place your order via phone

Toll Free No. :

Toll Free No. :

1800 121 3737

Or

request a callback

Applications

- Water supply - PVC-O pipes are primarily suitable for high-pressure water distribution systems in residential and commercial buildings where water safety is a critical concern.

- Irrigation piping - Food safety regulations require using safe water in irrigating agricultural lands. PVC-O pipes are the best choice in such applications.

- Industrial usages - Food processing, pharmaceuticals and similar industries with stringent water safety regulations use PVC(oriented) pipes.

- Multi-purpose pipes - PVC-O pipes are premium PVC with special advantages. We offer a wide range of Ultima PVC O Pipes for residential and industrial applications with an unmatched fit and finish.

Frequently Asked Questions

PVCO stands for Molecularly Oriented Polyvinyl Chloride. It is a type of pipe material made by stretching standard PVC under controlled conditions of pressure, temperature, and speed, aligning its molecules in a specific direction. This process significantly enhances its strength, toughness, and flexibility compared to regular PVC. PVCO pipes, often referred to as the next generation of PVC pipes, are utilised for high-pressure water applications due to their improved physical and mechanical properties. They are durable, impact-resistant, and suitable for various water transportation needs.

PVC-O pipes excel at transporting high-pressure water and are widely used in applications such as irrigation, potable water supply, fire extinguishing networks, and pumping systems. The unique molecular orientation process significantly enhances their strength and durability, making them ideal for demanding scenarios. These pipes offer unbeatable impact resistance, increased hydraulic capacity, and total water-tightness, ensuring reliable and efficient water transportation in diverse settings. Their versatility and resil of pipe material made by stretching standard PVC under controlled conditions of pressure, temperature, and speed, aligning its molecules in a specific direction. This process significantly enhances its strength, toughness, and flexibility compared to regular PVC. PVCO pipes, often referred to as the next generation of PVC pipes, are utilised for high-ience make PVC-O pipes a preferred choice for high-pressure water networks where strength, durability, and water-tightness are crucial.

The key difference between PVC (Polyvinyl Chloride) and PVC-O (Molecularly Oriented Polyvinyl Chloride) lies in their distinctive physical properties. PVC-O surpasses regular PVC in terms of strength, being notably stronger and more impact-resistant. Additionally, PVC-O boasts higher flexibility and crack resistance, showcasing superior toughness. In terms of weight, PVC-O pipes are lighter, enhanced strength, facilitating easier handling and installation. PVC-O tends to be more expensive, its extended lifespan and enhanced performance often justify the higher cost in various applications.

The full form of PVC-O pipe is "Molecularly Oriented Polyvinyl Chloride" pipe. It is a type of pipe material that undergoes a molecular orientation process, resulting in enhanced strength, durability, and flexibility compared to standard PVC pipes. PVC-O pipes are widely used for high-pressure water applications due to their superior physical and mechanical properties.

PVC-O pipe is manufactured through a specialised process known as molecular orientation. In this process, standard PVC (Polyvinyl Chloride) material is subjected to controlled conditions of pressure, temperature, and speed. The material is stretched to align its polymer molecules in a specific direction, resulting in a more ordered and structured form. This molecular orientation significantly enhances the strength, toughness, and flexibility of the PVC, making it suitable for high-pressure water applications. The degree of alignment can vary based on process parameters and the stretch ratio, allowing for customisation based on the desired properties of the PVC-O pipe.

.jpg)

.jpg)

.jpg)

.jpg)